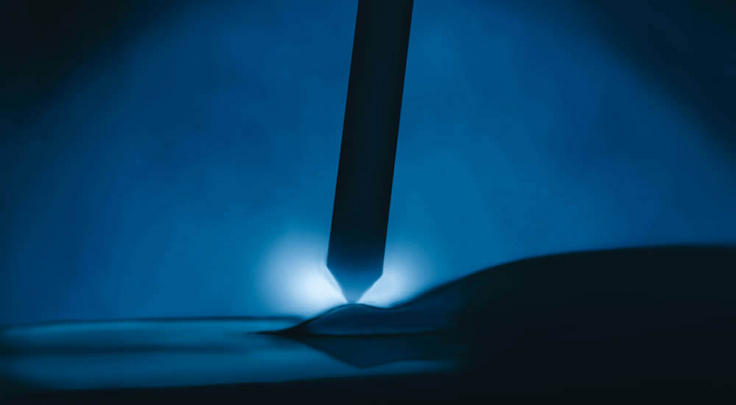

Control Weld - Through thick and thin

Control Weld covers the whole range of the controlled arc and is suitable for different applications. The classic MIG/MAG process offers a stable drop transfer from short arc to spray arc. At low power a short arc forms which is particularly advantageous when welding thin steel. When the power is increased the short arc turns to a spray arc. This process has more energy and there is more heat input in the base material and the wire than with the short arc process. Thus you reduce any time-consuming rework to a minimum thanks to the small short-circuit proof drop transfer with few spatters. Benefit from the versatile application possibilities of Control Weld. Do you search a reliable entry process for perfect welding quality? Then rely on Control Weld by CLOOS!

Your contact person

Christian Paul

Tel.: +49 (0)2773/85-565

Click here to find suitable solutions

View solutionsThese processes could interest you