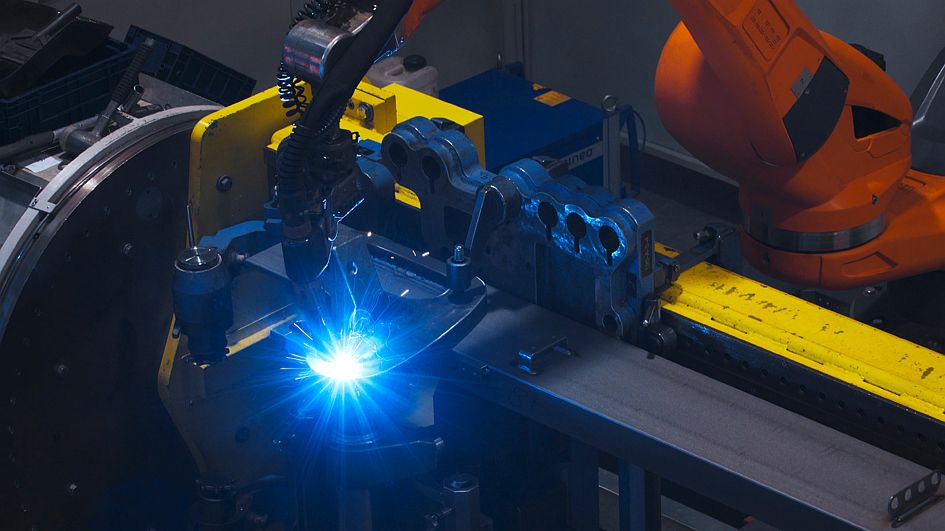

Flexible robot welding system with offline programming at Linde Material Handling

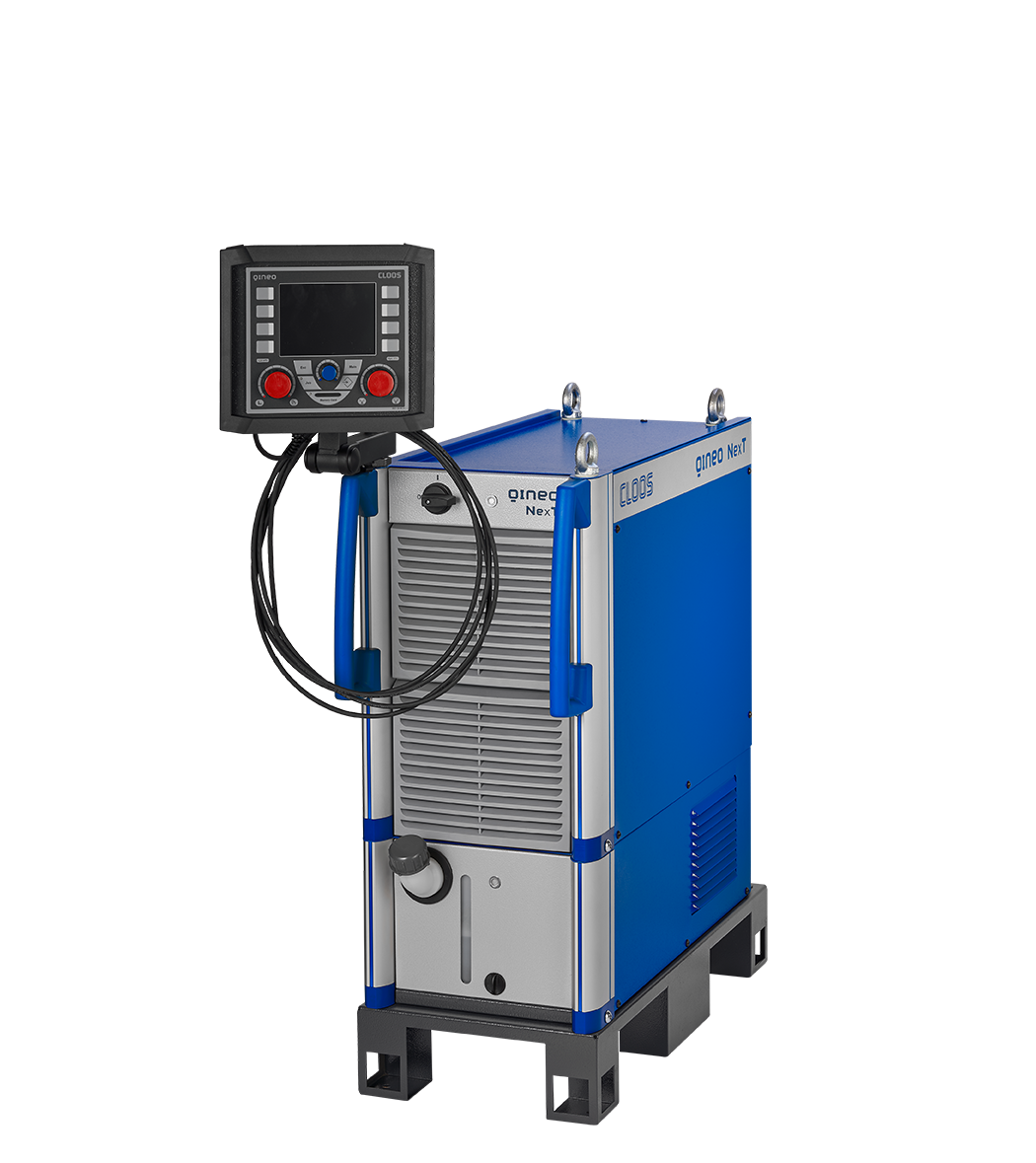

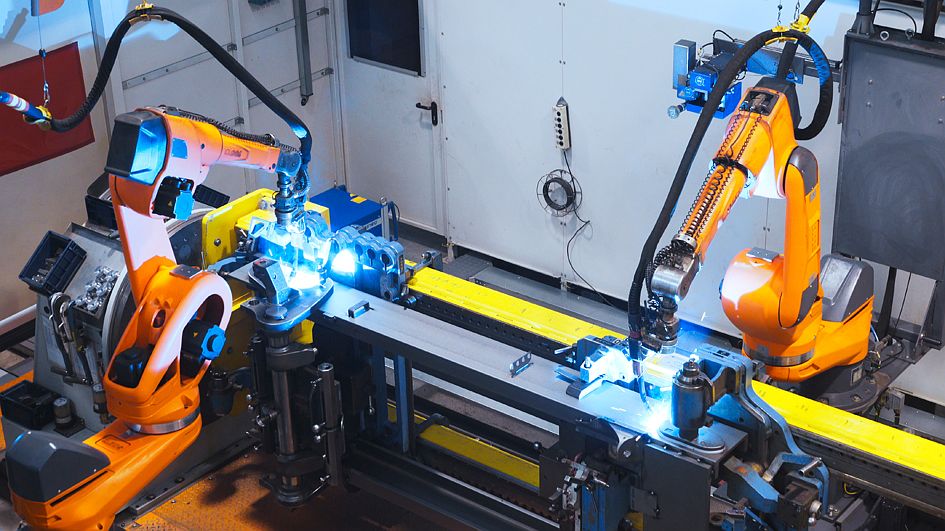

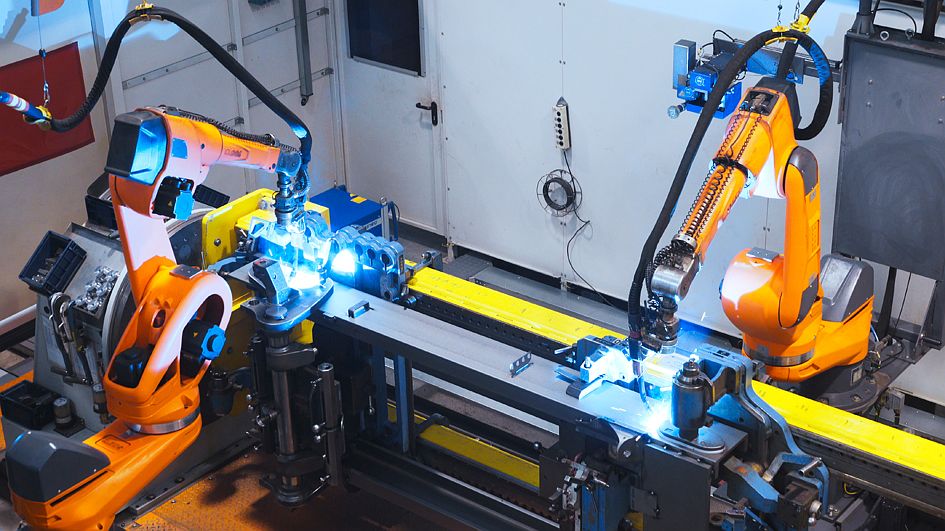

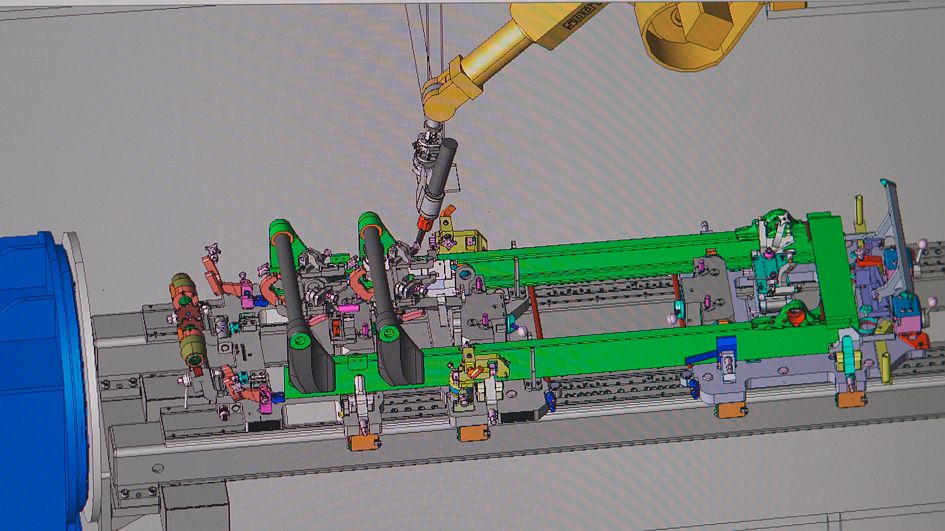

As one of the world's largest manufacturers of forklift trucks and warehouse equipment, Linde Material Handling GmbH relies on CLOOS technologies for both manual and automated welding at its production site in Aschaffenburg. The flexible robot welding system in the lift mast production area was individually adapted to the special conditions on site. As the production hall has a low ceiling height, the system is relatively wide. The two welding robots are located in the middle of the system, while a track flexibly moves the positioners back and forth between the two stations. Due to the large number of variants, Linde Material Handling uses the offline programming software RoboPlan from CLOOS for automated welding. While production is running in the robot system, a new program can be created in RoboPlan at the same time. Here, welding, search and travel paths and tools are defined on 3D models, for which the welding parameters and other functions required for running the program are then defined.