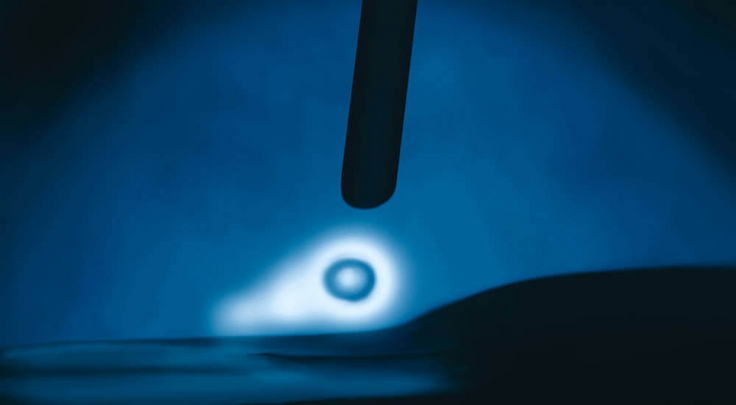

Vari Weld - for aluminium welding and MIG brazing

Vari Weld is particularly suitable for aluminium applications, cladding or welds with special requirements regarding the appearance of the weld surface. The Vari Weld process creates an extremely low spatter pulsed arc. Due to the low welding temperature the base material remains metallurgically unaffected and the corrosion protection is maintained. This process offers completely stable arc conditions and an outstanding controllable weld pool even under varying external influences. You keep the original material properties because of the minimised heat input. You avoid extensive reworks thanks to the reduced component distortion. So you achieve optimum welding results even under demanding conditions. Do you wish a reliable welding process for excellent quality? Then rely on Vari Weld by CLOOS!

Your contact person

Christian Paul

Tel.: +49 (0)2773/85-565

Click here to find suitable solutions

View solutionsThese processes could interest you