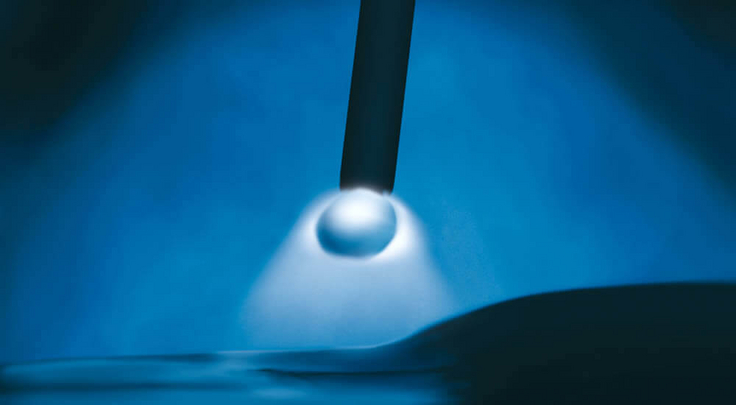

Cold Weld - Welding with minimum heat input

Due to the minimum heat input, Cold Weld is perfectly suitable for thin plates and heat sensitive materials such as aluminium or high-strength steel. Cold Weld combines a pulsed arc with AC technology. In the case of positive (classic) wire polarity the arc starts at the wire end and couples only few energy into the free wire end. Most of the arc energy is led into the workpiece. In the case of negative polarity the arc attachment spot on the free wire end goes up and encloses a large part of the wire. Thus more heat is coupled in the free wire end. The wire gets hotter and the deposition rate increases considerably. This causes less heat input in the material and less load for the component. By means of the polarity ratio the heat input in the component can be controlled very precisely. Thus the heat input can be controlled perfectly. With Cold Weld you reduce your welding times due to the high deposition rate. You keep the original material properties because of the minimised heat input. You reduce the component distortion and avoid extensive reworks. You compensate material tolerances due to the good gap bridging ability. Do you wish to reduce your production costs for thin plates and to increase the quality at the same time? Then rely on Cold Weld by CLOOS!

Your contact person

Christian Paul

Tel.: +49 (0)2773/85-565

Click here to find suitable solutions

View solutionsThese processes could interest you