Customer:Ernst Kern GmbH

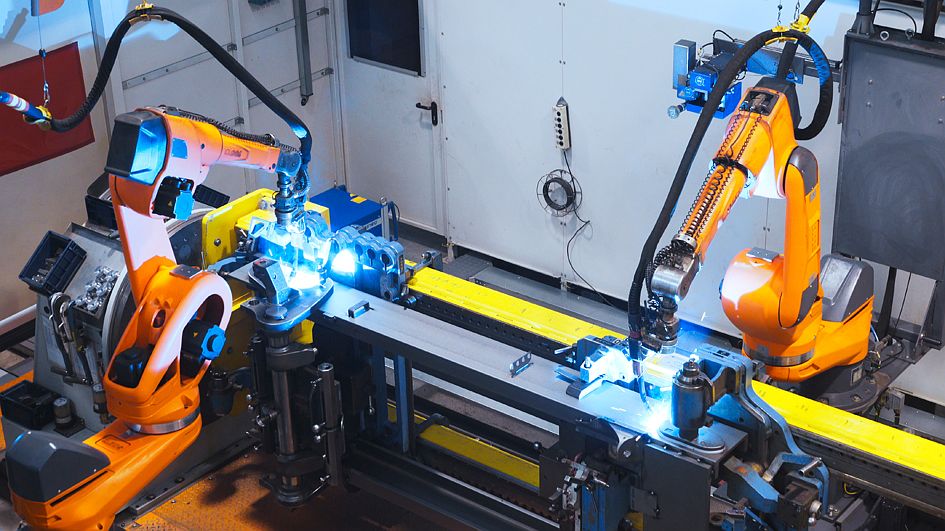

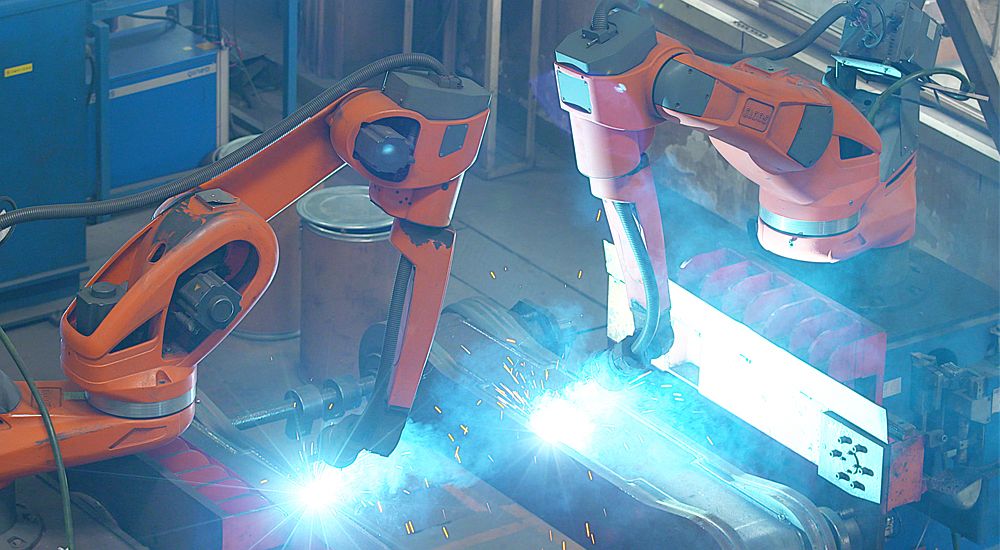

Customer:Ernst Kern GmbH Customer:KION StribroComponent:Lift mast for forklift truck

Customer:KION StribroComponent:Lift mast for forklift truck Customer:muli-cycles GmbHComponent:Bicycle frame

Customer:muli-cycles GmbHComponent:Bicycle frame Customer:Schwevers & RaabComponent:Hall girder

Customer:Schwevers & RaabComponent:Hall girder Customer:GlüpkerComponent:Chassis

Customer:GlüpkerComponent:Chassis Customer:Bieber Industrie SASComponent:Machine base frame

Customer:Bieber Industrie SASComponent:Machine base frame Customer:Rosenbauer Karlsruhe GmbHComponent:Tapered support tube

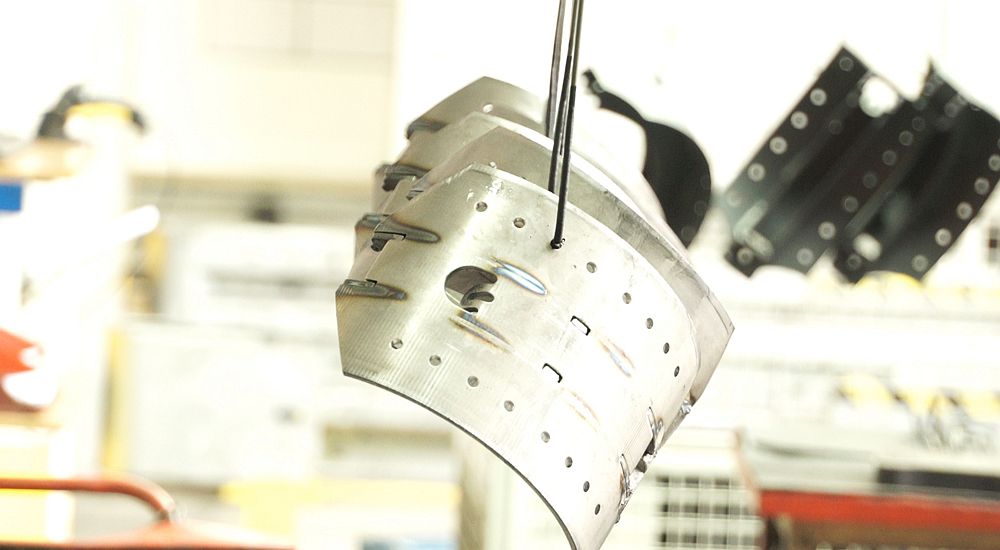

Customer:Rosenbauer Karlsruhe GmbHComponent:Tapered support tube Customer:Henke GmbHComponent:Crossbar for luggage carrier

Customer:Henke GmbHComponent:Crossbar for luggage carrier Customer:Henke GmbHComponent:Switch cabinet

Customer:Henke GmbHComponent:Switch cabinet Customer:Nußbaum GmbH & Co KGComponent:Mast for vehicle lift

Customer:Nußbaum GmbH & Co KGComponent:Mast for vehicle lift Customer:Nußbaum GmbH & Co KGComponent:Parts for vehicle lift

Customer:Nußbaum GmbH & Co KGComponent:Parts for vehicle lift Customer:Kohl & Sohn GmbHComponent:Cover hood

Customer:Kohl & Sohn GmbHComponent:Cover hood Customer:GlüpkerComponent:Protective housing

Customer:GlüpkerComponent:Protective housing Customer:SAF-Holland GmbHComponent:Support

Customer:SAF-Holland GmbHComponent:Support Customer:Henan JuntonComponent:Small parts for tipper

Customer:Henan JuntonComponent:Small parts for tipper Customer:Henan JuntonComponent:Small parts for tipper

Customer:Henan JuntonComponent:Small parts for tipper Customer:Henan JuntonComponent:Gearbox housing

Customer:Henan JuntonComponent:Gearbox housing Customer:Linde Material Handling GmbHComponent:Lift mast for forklift truck

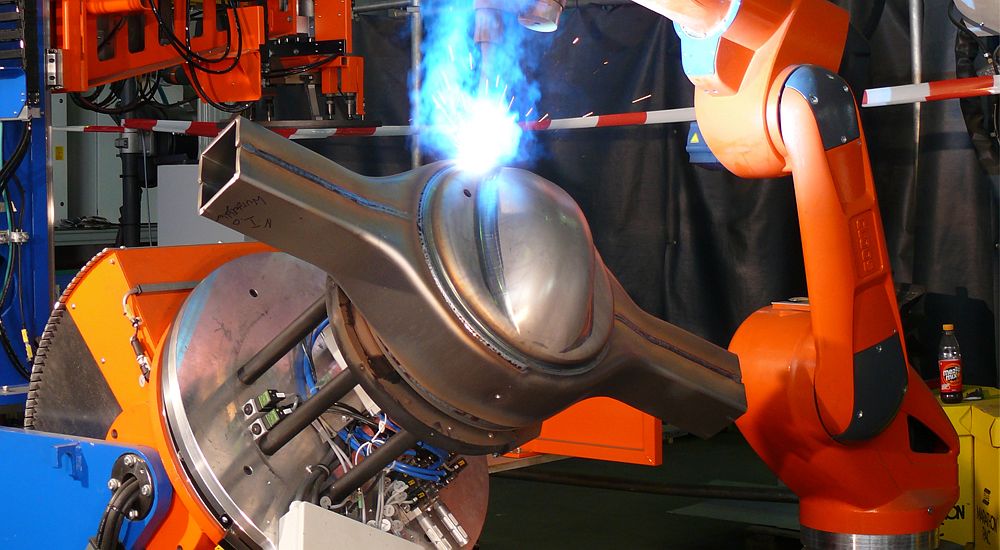

Customer:Linde Material Handling GmbHComponent:Lift mast for forklift truck Customer:Rosenbauer Karlsruhe GmbHComponent:Tapered support tube

Customer:Rosenbauer Karlsruhe GmbHComponent:Tapered support tube Customer:GlüpkerComponent:Head frame for semi-trailers

Customer:GlüpkerComponent:Head frame for semi-trailers Customer:BPW Bergische Achsen KGComponent:Axle support for semi-trailer

Customer:BPW Bergische Achsen KGComponent:Axle support for semi-trailer Customer:Thoclatec GmbHComponent:Retaining plate

Customer:Thoclatec GmbHComponent:Retaining plate Customer:VIESSMANN WERKE BERLIN GMBHComponent:Boiler

Customer:VIESSMANN WERKE BERLIN GMBHComponent:Boiler Customer:ORION-BAUSYSTEME GMBHComponent:Bicycle parking

Customer:ORION-BAUSYSTEME GMBHComponent:Bicycle parking Customer:Glüpker Blechtechnologie GmbHComponent:Stage

Customer:Glüpker Blechtechnologie GmbHComponent:Stage Customer:Puky GmbH & Co KGComponent:Bicycle handlebars

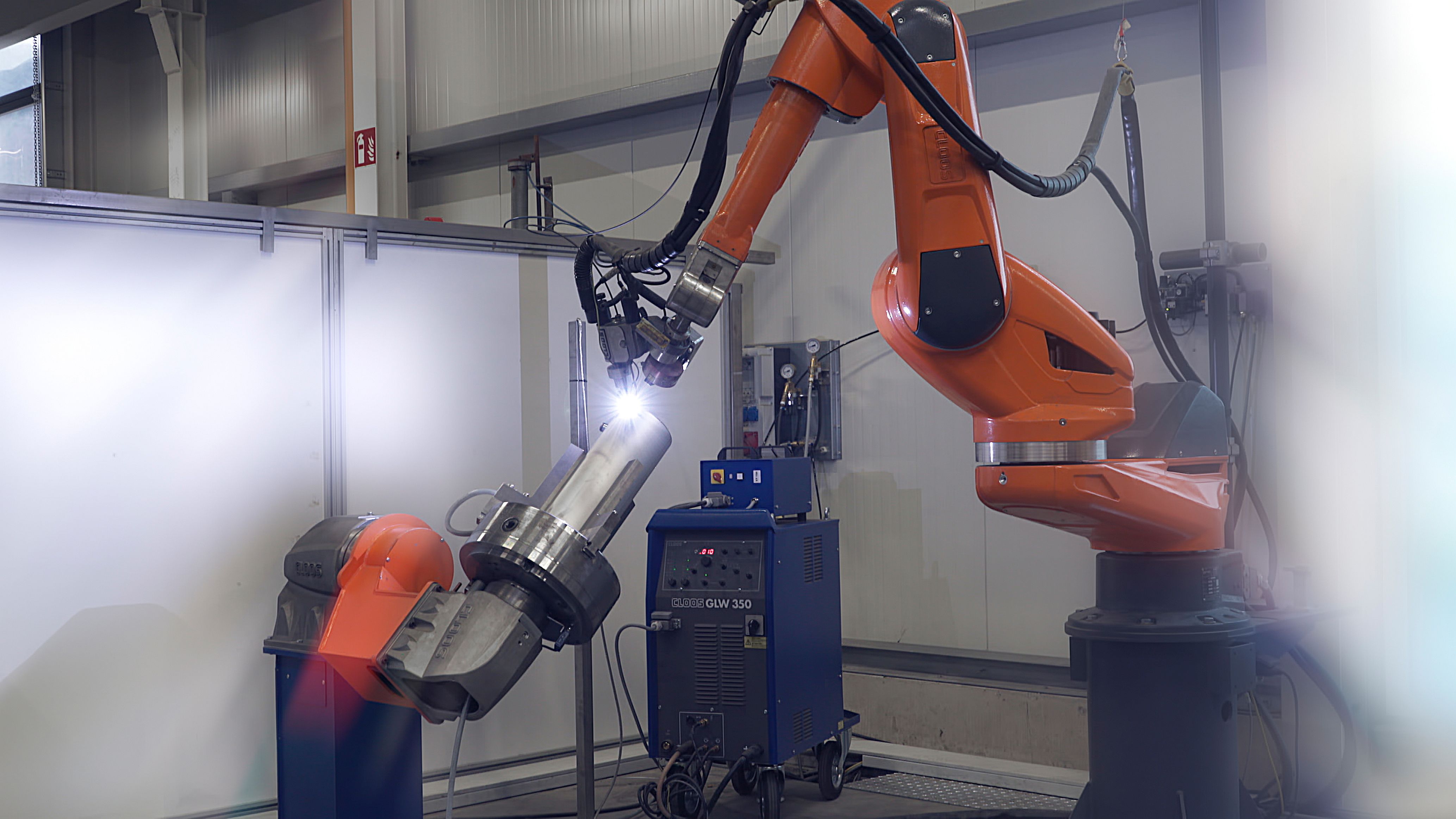

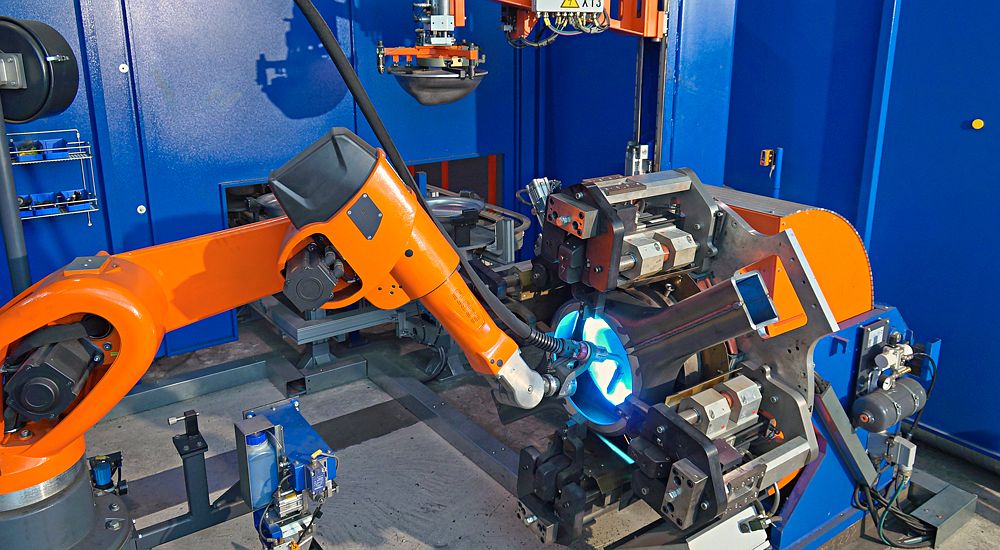

Customer:Puky GmbH & Co KGComponent:Bicycle handlebars Customer:LTI-Metalltechnik GmbHComponent:Fan wheels

Customer:LTI-Metalltechnik GmbHComponent:Fan wheels Customer:AtmosComponent:Boiler

Customer:AtmosComponent:Boiler Customer:Werkzeugsysteme Müller GmbHComponent:Barrel

Customer:Werkzeugsysteme Müller GmbHComponent:Barrel Customer:H+G Disposal SystemsComponent:Screw compressor housing

Customer:H+G Disposal SystemsComponent:Screw compressor housing Customer:H+G Disposal SystemsComponent:Screw compressor housing

Customer:H+G Disposal SystemsComponent:Screw compressor housing Customer:Rudolf Hörmann GmbH & Co.KGComponent:Railing

Customer:Rudolf Hörmann GmbH & Co.KGComponent:Railing Customer:Rudolf Hörmann GmbH & Co.KGComponent:Railing

Customer:Rudolf Hörmann GmbH & Co.KGComponent:Railing Customer:Langmatz GmbHComponent:Manhole cover

Customer:Langmatz GmbHComponent:Manhole cover Customer:Fritz Driescher KG Spezialfabrik f.Component:Protective housing

Customer:Fritz Driescher KG Spezialfabrik f.Component:Protective housing Customer:Lemken GmbH & Co KGComponent:Fitness equipment

Customer:Lemken GmbH & Co KGComponent:Fitness equipment Customer:H.K. Heun GmbHComponent:Water tank

Customer:H.K. Heun GmbHComponent:Water tank Customer:KUHN S.A.Component:Discs for mowing machines

Customer:KUHN S.A.Component:Discs for mowing machines Customer:GlüpkerComponent:Handle

Customer:GlüpkerComponent:Handle Customer:Puky GmbH & Co KGComponent:Bicycle frame

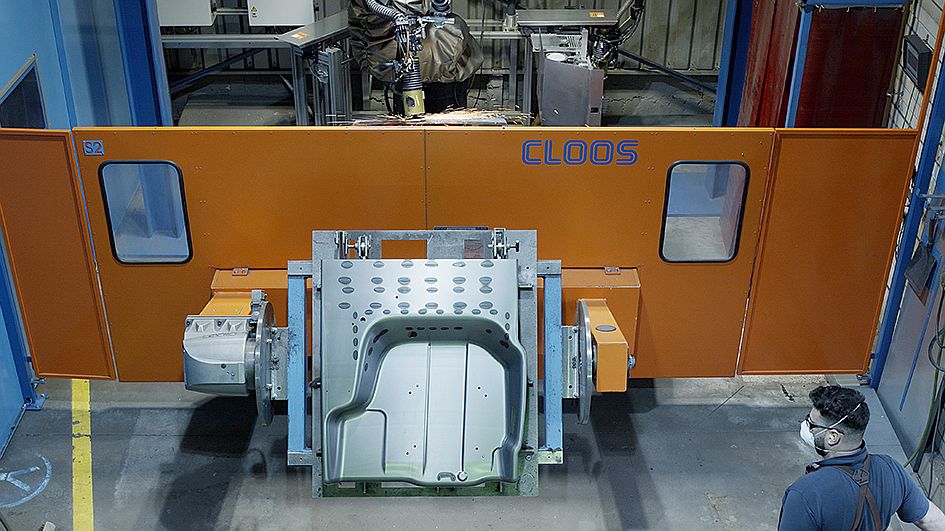

Customer:Puky GmbH & Co KGComponent:Bicycle frame Customer:AGCO GmbHComponent:Cabins

Customer:AGCO GmbHComponent:Cabins Customer:GlüpkerComponent:Scuff plate

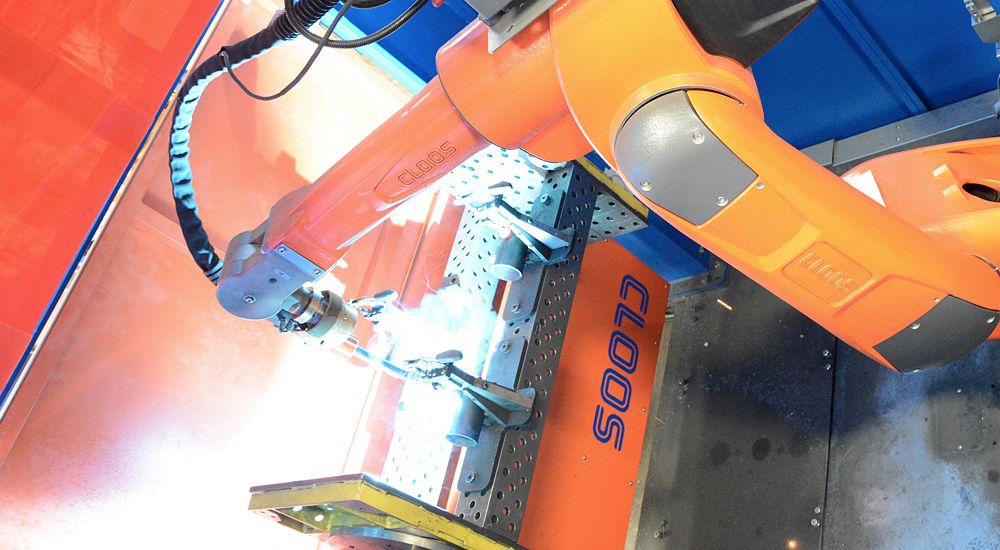

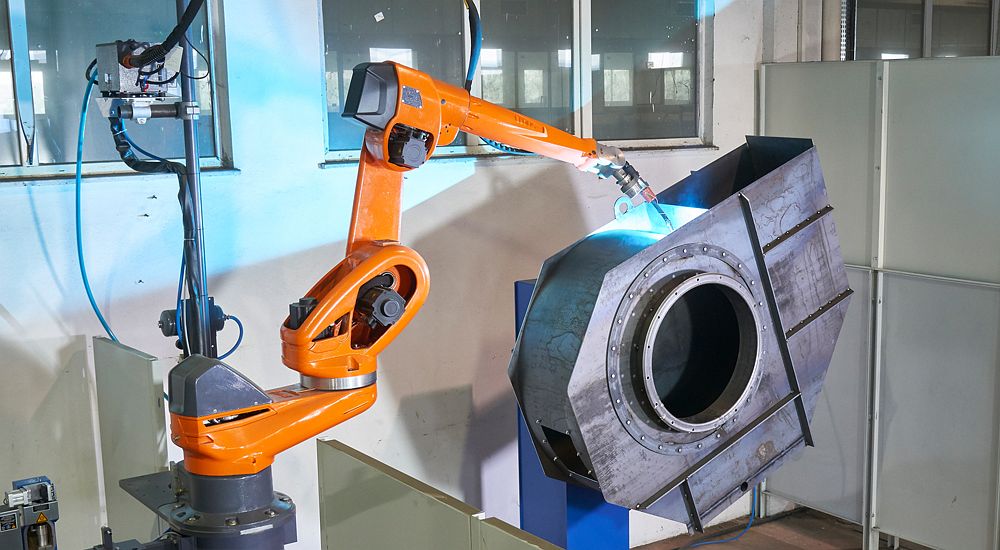

Customer:GlüpkerComponent:Scuff plate Customer:Incircioglu Vantilator KlimaComponent:Fan housing

Customer:Incircioglu Vantilator KlimaComponent:Fan housing Customer:Halder ToolsComponent:Soft-face mallet

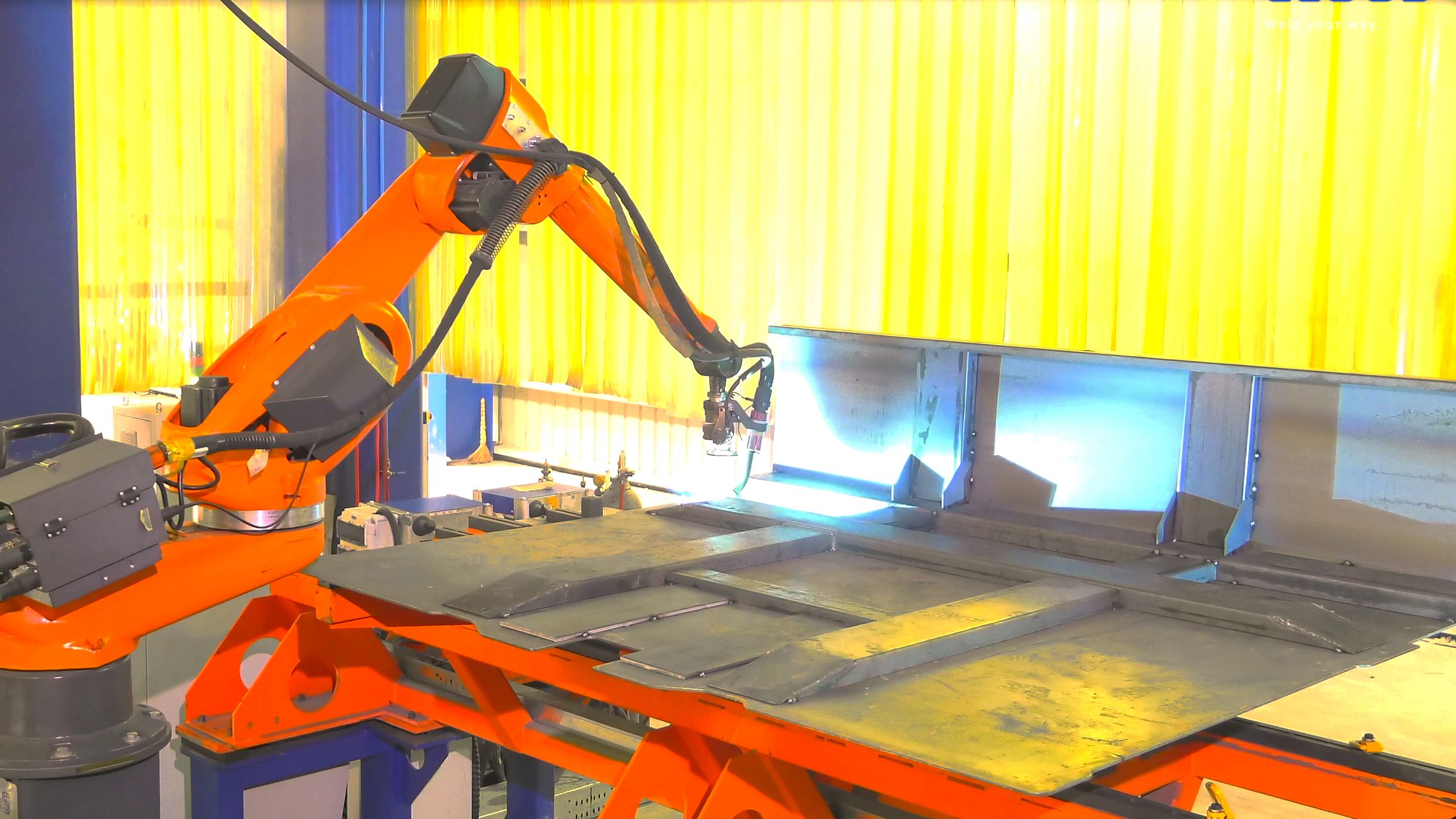

Customer:Halder ToolsComponent:Soft-face mallet Customer:Meiller Slany s.r.o.Component:Tipper body side wall

Customer:Meiller Slany s.r.o.Component:Tipper body side wall Customer:Meiller Slany s.r.o.Component:Rear wall of tipper body

Customer:Meiller Slany s.r.o.Component:Rear wall of tipper body Customer:Albert-Frankenthal GmbHComponent:Rollers for printing machines

Customer:Albert-Frankenthal GmbHComponent:Rollers for printing machines Customer:Langmatz GmbHComponent:Manhole cover

Customer:Langmatz GmbHComponent:Manhole cover Customer:Stahl- und Metallbau Ihnencomponent:Stage

Customer:Stahl- und Metallbau Ihnencomponent:Stage Customer:Zhengzhou Coal MiningComponent:Connector for extension shields

Customer:Zhengzhou Coal MiningComponent:Connector for extension shields Customer:H.K. Heun GmbHComponent:Ladder for civil engineering

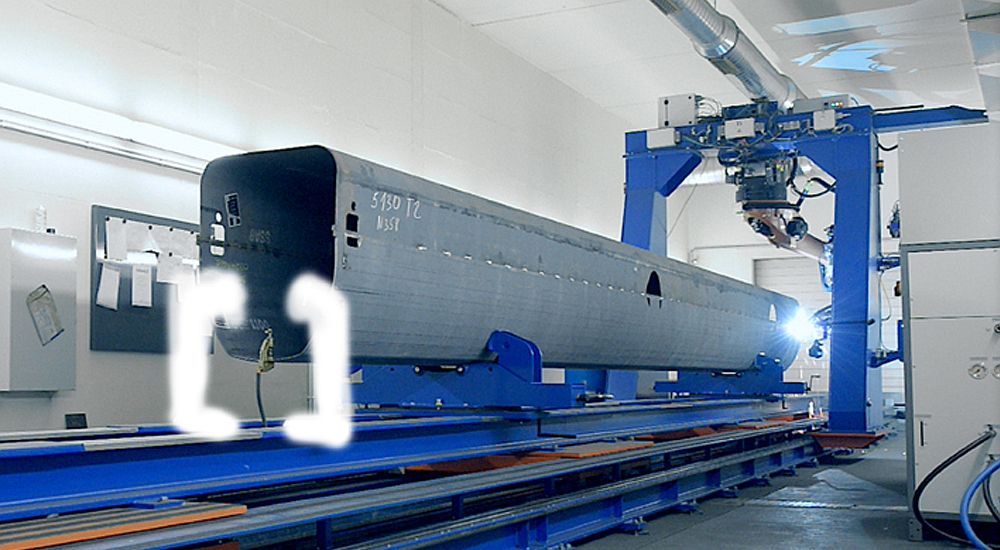

Customer:H.K. Heun GmbHComponent:Ladder for civil engineering Customer:MANITOWOC Crane Group Germany GmbHComponent:Telescopic boom

Customer:MANITOWOC Crane Group Germany GmbHComponent:Telescopic boom Customer:AKP Otomotiv San. Tic, Ltd. Sti.Component:Fuel tank

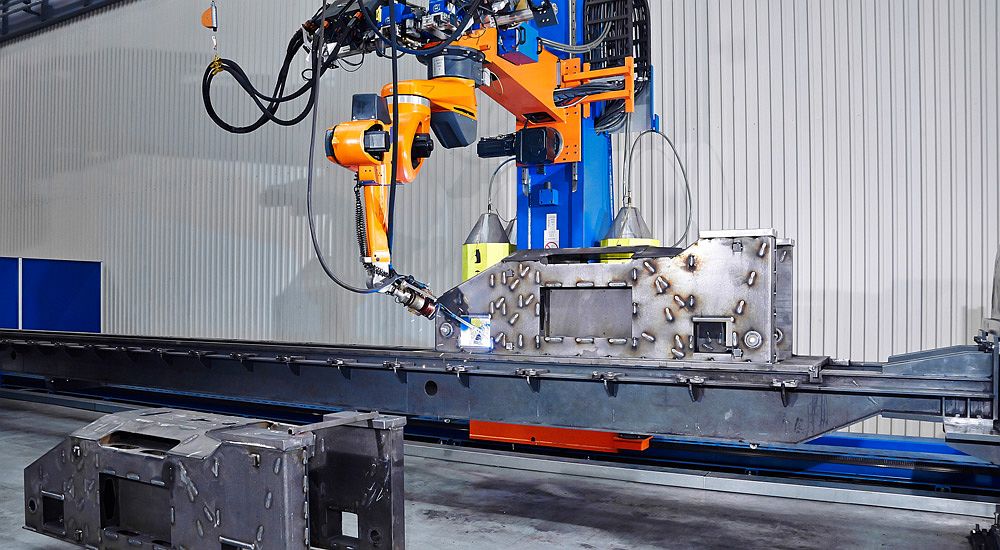

Customer:AKP Otomotiv San. Tic, Ltd. Sti.Component:Fuel tank Customer:Meiller Slany s.r.o.Component:Base plate for tipper body

Customer:Meiller Slany s.r.o.Component:Base plate for tipper body Customer:Meiller Slany s.r.o.Component:Tipper body

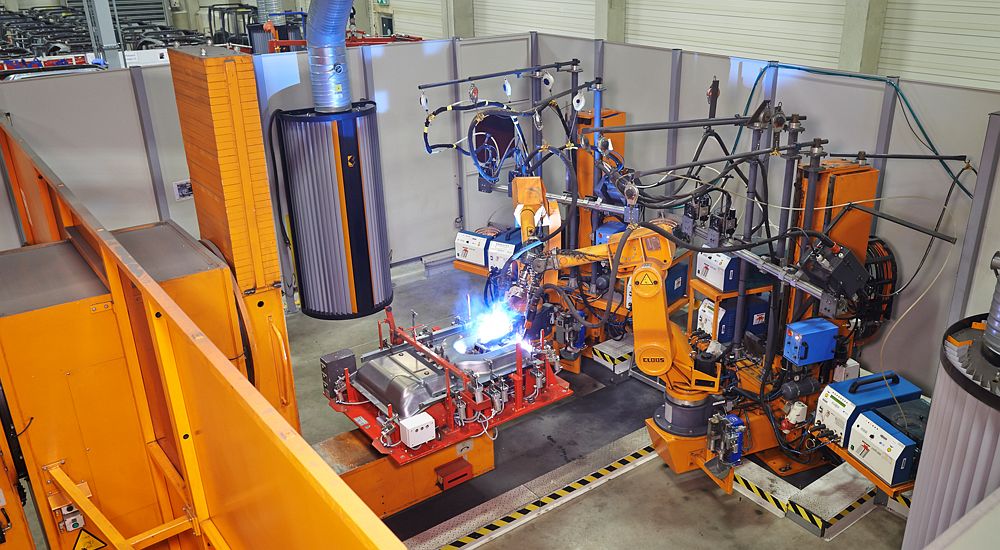

Customer:Meiller Slany s.r.o.Component:Tipper body Customer:AGCO GmbHComponent:Tractor cab

Customer:AGCO GmbHComponent:Tractor cab Customer:AGCO GmbHComponent:Tractor cab

Customer:AGCO GmbHComponent:Tractor cab Customer:Hilge GmbH & Co. KGComponent:Pump housing Impeller

Customer:Hilge GmbH & Co. KGComponent:Pump housing Impeller Customer:SSI Schäfer s.r.o.Component:Storage and retrieval machine

Customer:SSI Schäfer s.r.o.Component:Storage and retrieval machine Customer:MBH Mechanical EngineeringComponent:Chassis

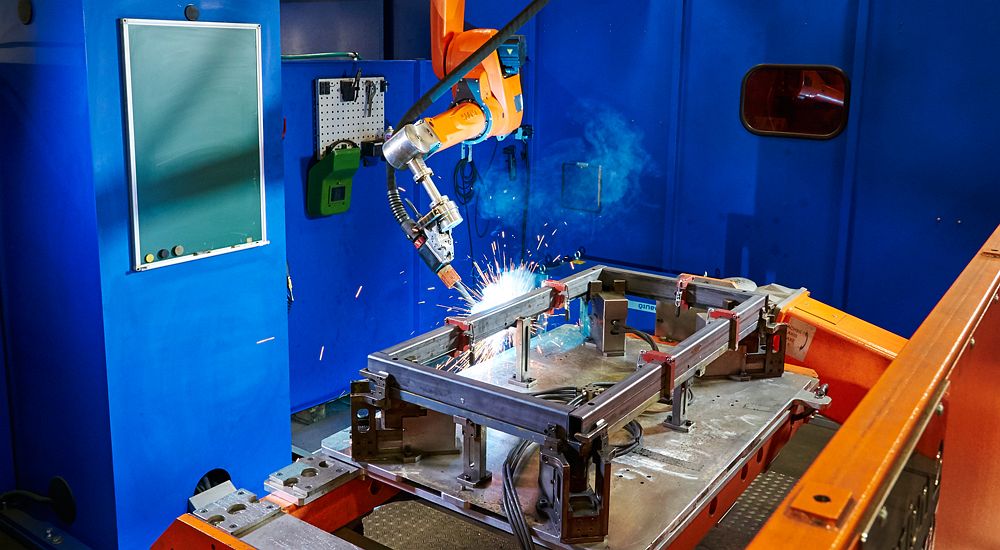

Customer:MBH Mechanical EngineeringComponent:Chassis Customer:Matyssek Metalltechnik GmbHComponent:Machine base frame

Customer:Matyssek Metalltechnik GmbHComponent:Machine base frame Customer:Matyssek Metalltechnik GmbHComponent:Cover hood

Customer:Matyssek Metalltechnik GmbHComponent:Cover hood Customer:Matyssek Metalltechnik GmbHComponent:Inner frame

Customer:Matyssek Metalltechnik GmbHComponent:Inner frame Customer:Matyssek Metalltechnik GmbHComponent:Protective housing

Customer:Matyssek Metalltechnik GmbHComponent:Protective housing Customer:STE SANA SAComponent:Boiler

Customer:STE SANA SAComponent:Boiler Customer:AGCO GmbHComponent:Tractor cab

Customer:AGCO GmbHComponent:Tractor cab Customer:AGCO GmbHComponent:Tractor cab

Customer:AGCO GmbHComponent:Tractor cab Customer:Stahl- und Metallbau Ihnencomponent:Spinner carrier

Customer:Stahl- und Metallbau Ihnencomponent:Spinner carrier Customer:Wessel GmbHComponent:Heat exchanger tube

Customer:Wessel GmbHComponent:Heat exchanger tube Customer:voestalpine Anarbeitung GmbHComponent:Axle bridge - ring

Customer:voestalpine Anarbeitung GmbHComponent:Axle bridge - ring Customer:voestalpine Anarbeitung GmbHComponent:Axle bridge - cover

Customer:voestalpine Anarbeitung GmbHComponent:Axle bridge - cover Customer:voestalpine Anarbeitung GmbHComponent:Axle bridge - top layer

Customer:voestalpine Anarbeitung GmbHComponent:Axle bridge - top layer Customer:voestalpine Anarbeitung GmbHComponent:Axle bridge - root seam

Customer:voestalpine Anarbeitung GmbHComponent:Axle bridge - root seam Customer:Stahl- und Metallbau Ihnencomponent:Spinner carrier

Customer:Stahl- und Metallbau Ihnencomponent:Spinner carrier Customer:TATRAVAGONKA POPRADcomponent:Bogie

Customer:TATRAVAGONKA POPRADcomponent:Bogie